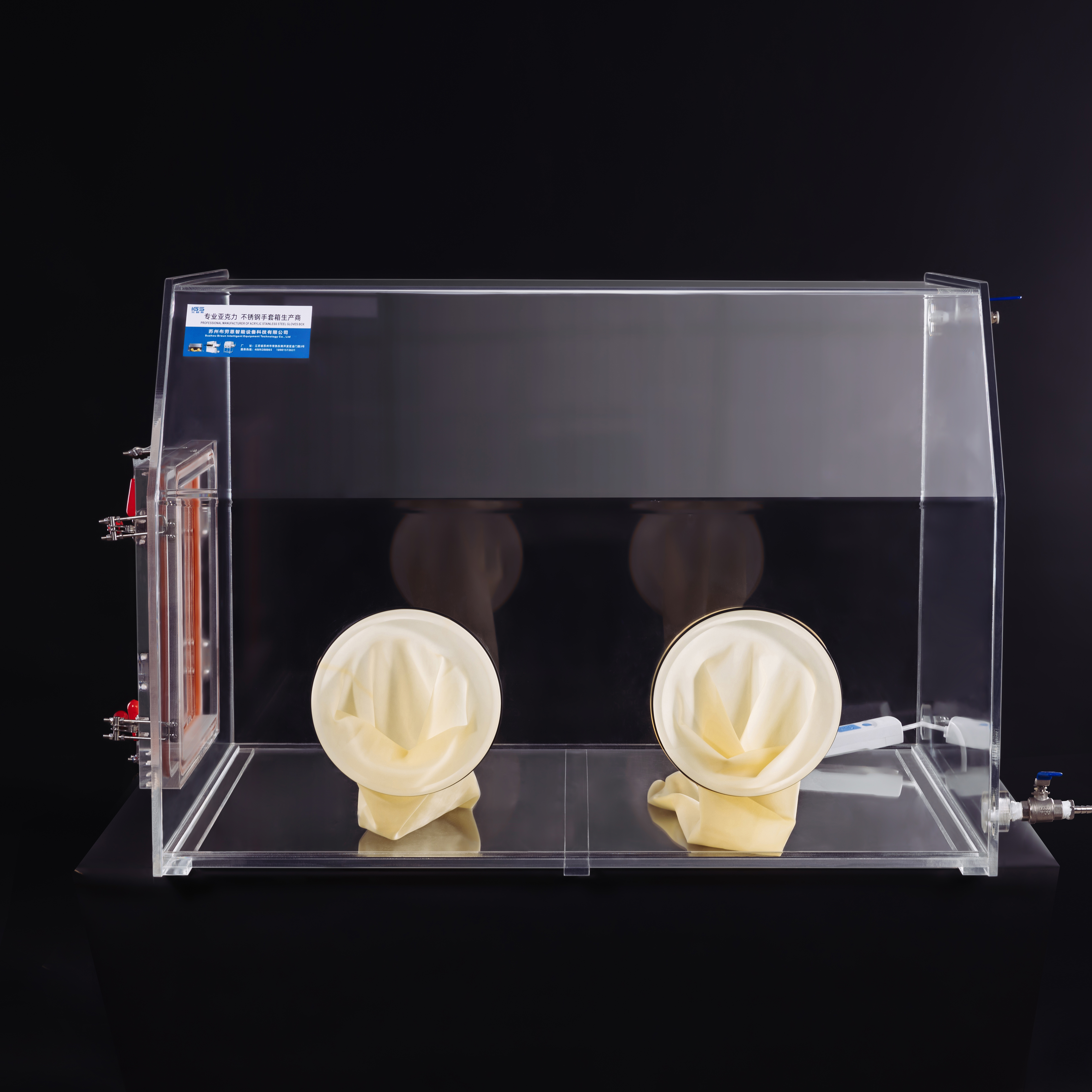

vacuum technology glovebox

The vacuum technology glovebox is an advanced piece of equipment designed to provide an airtight, controlled environment for handling materials sensitive to air and moisture. Its main functions include sample manipulation, material processing, and the ability to perform experiments in an inert atmosphere. Technological features such as airtight seals, advanced vacuum systems, and integrated gas handling make it an indispensable tool in various industries. Applications range from scientific research and electronics manufacturing to pharmaceutical development and the handling of precious metals. With its robust design and precise controls, the vacuum technology glovebox ensures the integrity of materials while facilitating intricate operations.