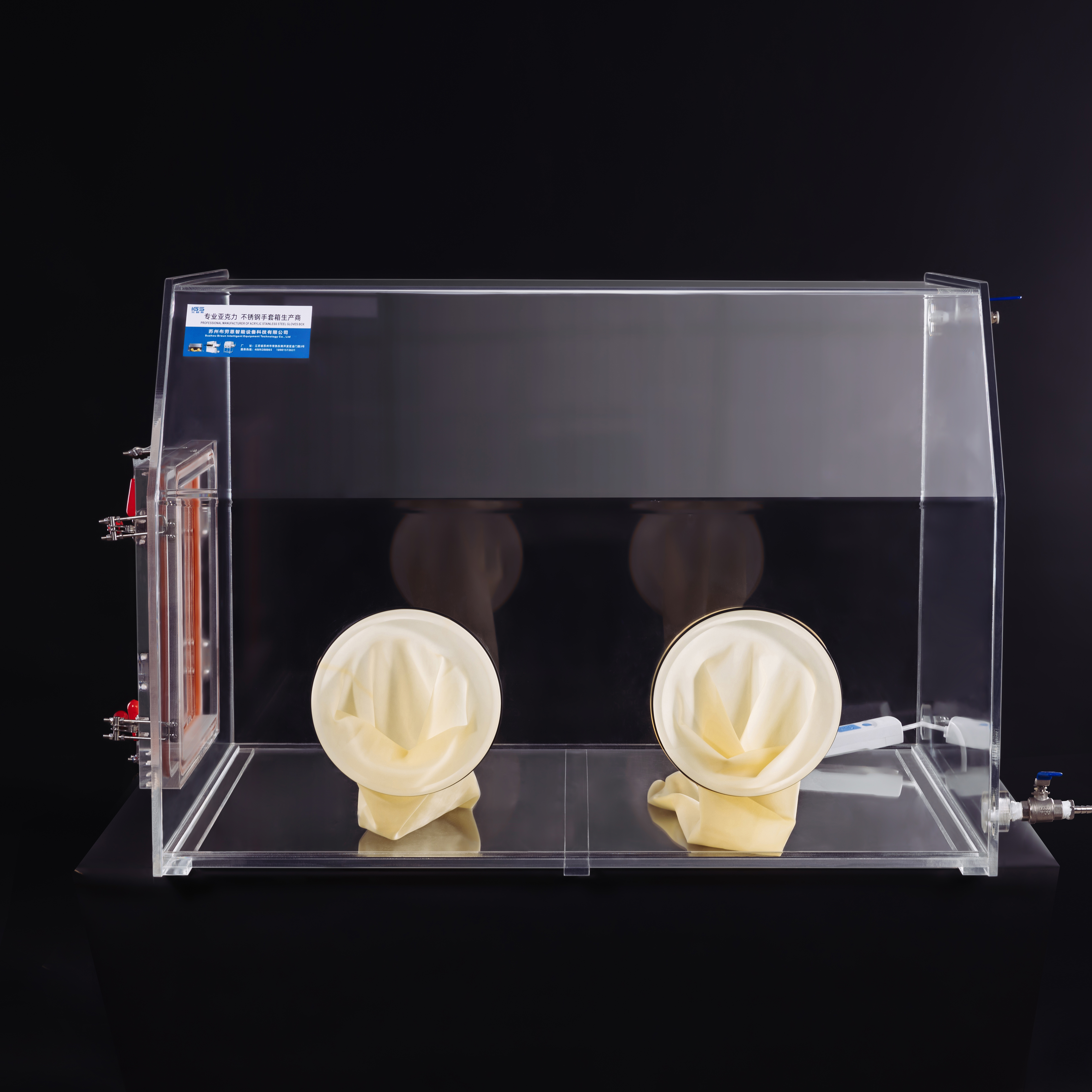

control oxygen sensitive acrylic glove box

The control oxygen sensitive acrylic glove box is a state-of-the-art piece of equipment designed for handling materials that are sensitive to oxygen and moisture. Its main functions include providing an inert atmosphere for the storage and handling of reactive substances and ensuring the integrity of oxygen-sensitive products. Technological features such as a robust acrylic construction, airtight seals, and an integrated gas purging system contribute to its effectiveness. Applications span across various industries including pharmaceuticals, electronics, and materials science where the handling of oxygen-sensitive compounds is critical. With programmable controls for atmosphere regulation and user-friendly interfaces, this glove box is an essential tool for research and production in oxygen-sensitive environments.