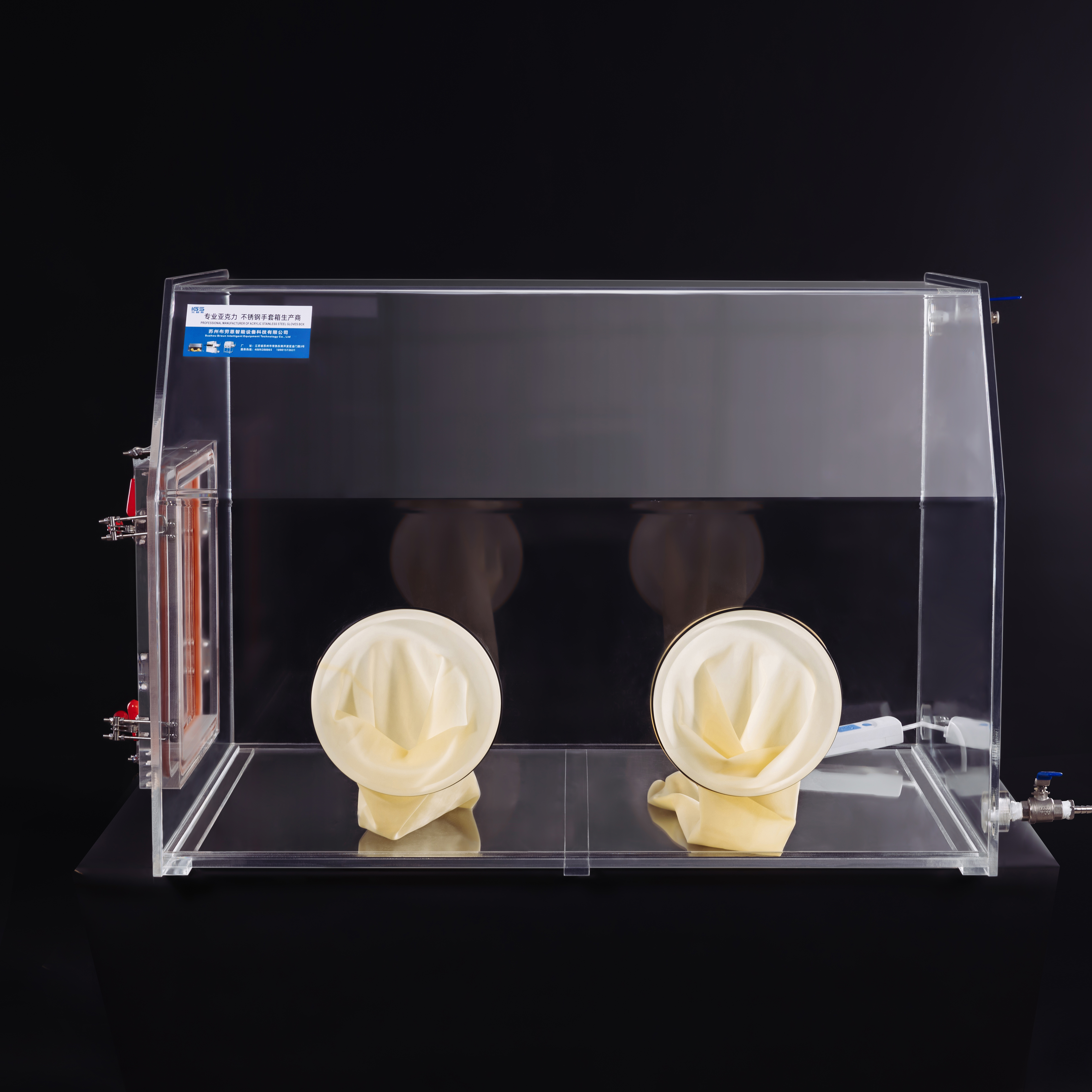

Enhanced Safety for Operators

The design of the argon filled glove box prioritizes operator safety, especially when dealing with toxic, volatile, or flammable substances. The sealed system ensures that these materials are contained securely within the chamber, eliminating the risk of exposure and inhalation. Moreover, the glove ports allow for meticulous manipulation without the need for direct contact, significantly reducing the chance of laboratory accidents. This safety feature not only protects the operator but also the environment, preventing the release of harmful substances into the laboratory space.