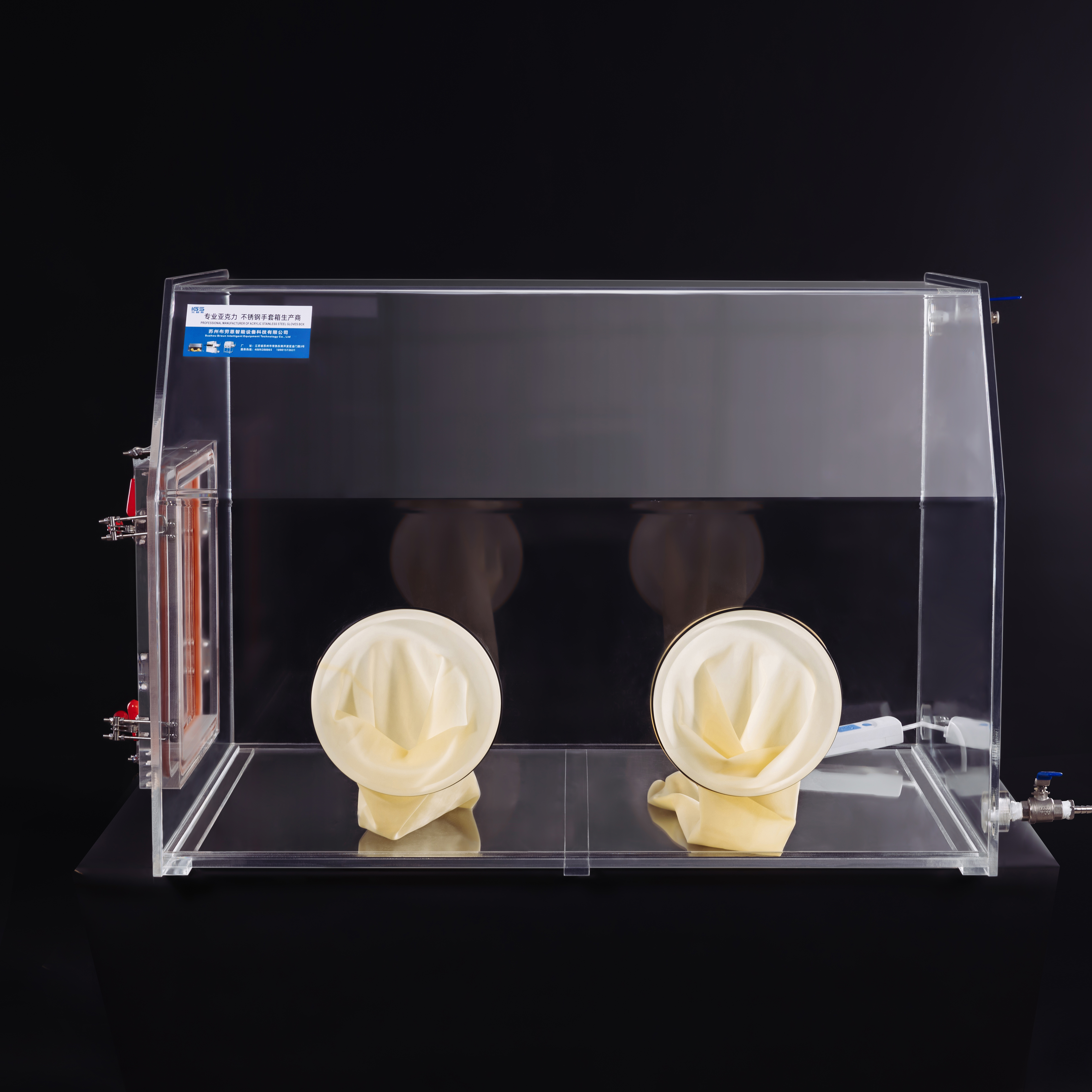

purified glovebox gas system

The purified glovebox gas system is an innovative solution designed to provide a controlled, contamination-free environment for handling gases and materials sensitive to atmospheric exposure. This system's main functions include the purification of gases, the maintenance of an inert atmosphere, and the safe containment of materials during processing. Technological features such as advanced filtration systems, precision controls, and a sealed, modular design ensure optimal performance and flexibility. Applications span across various industries, including pharmaceuticals, electronics, and materials science, where the integrity of materials is crucial. The system effectively prevents contamination, enabling researchers and manufacturers to conduct work with high purity standards.