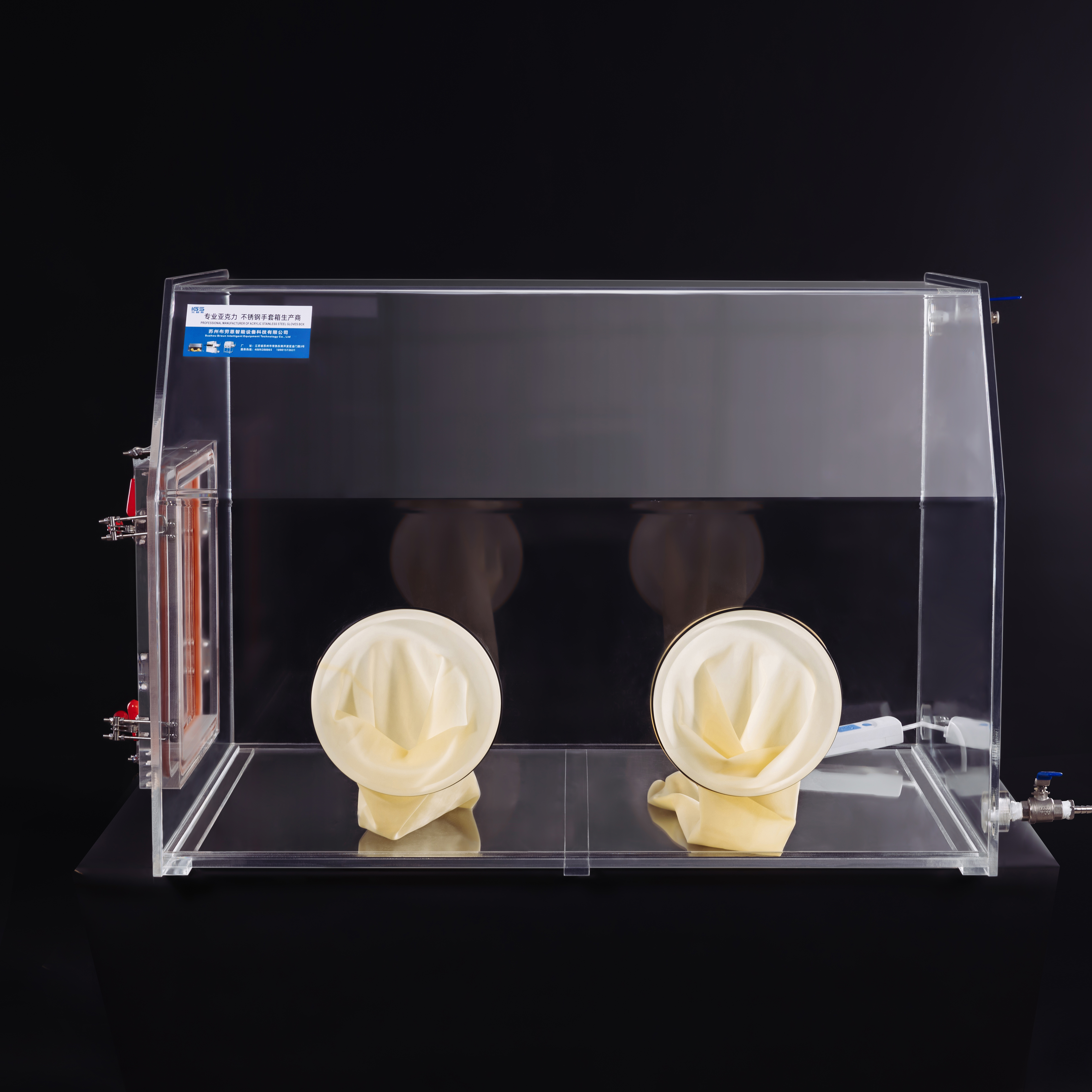

inert gas glove box

The inert gas glove box is a state-of-the-art piece of equipment designed for handling materials that react with air or moisture. Its main functions include the creation of an airtight, oxygen-free environment, which is essential for experiments or handling substances that require an inert atmosphere. Technological features of the glove box include a robust stainless steel construction, advanced filtration systems, and precise control over the internal atmosphere with integrated gas flow systems. These features allow for the manipulation of sensitive materials without the risk of contamination. Applications of the inert gas glove box span across various industries, including pharmaceuticals, electronics, and advanced material research.