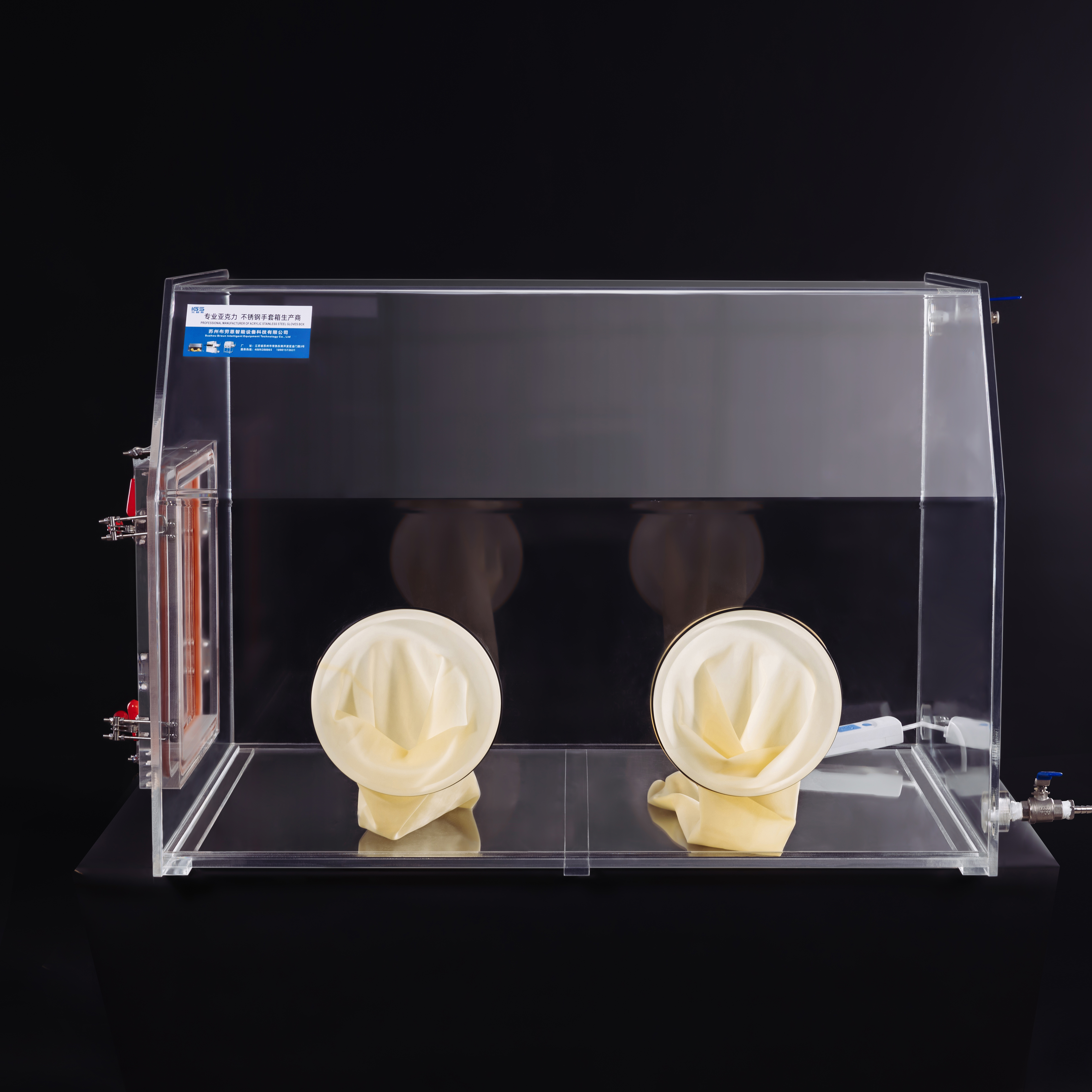

Advanced Filtration Systems

One of the unique selling points of glove box manufacturers is their integration of advanced filtration systems. These systems ensure that the internal atmosphere remains free from contaminants, critical for applications requiring a sterile environment. The importance of this feature cannot be overstated, as it directly impacts the reliability of research results and the quality of manufactured goods. For customers, this means peace of mind, knowing that their processes are not compromised by environmental factors, leading to consistent and reproducible outcomes.