glovebox chemistry

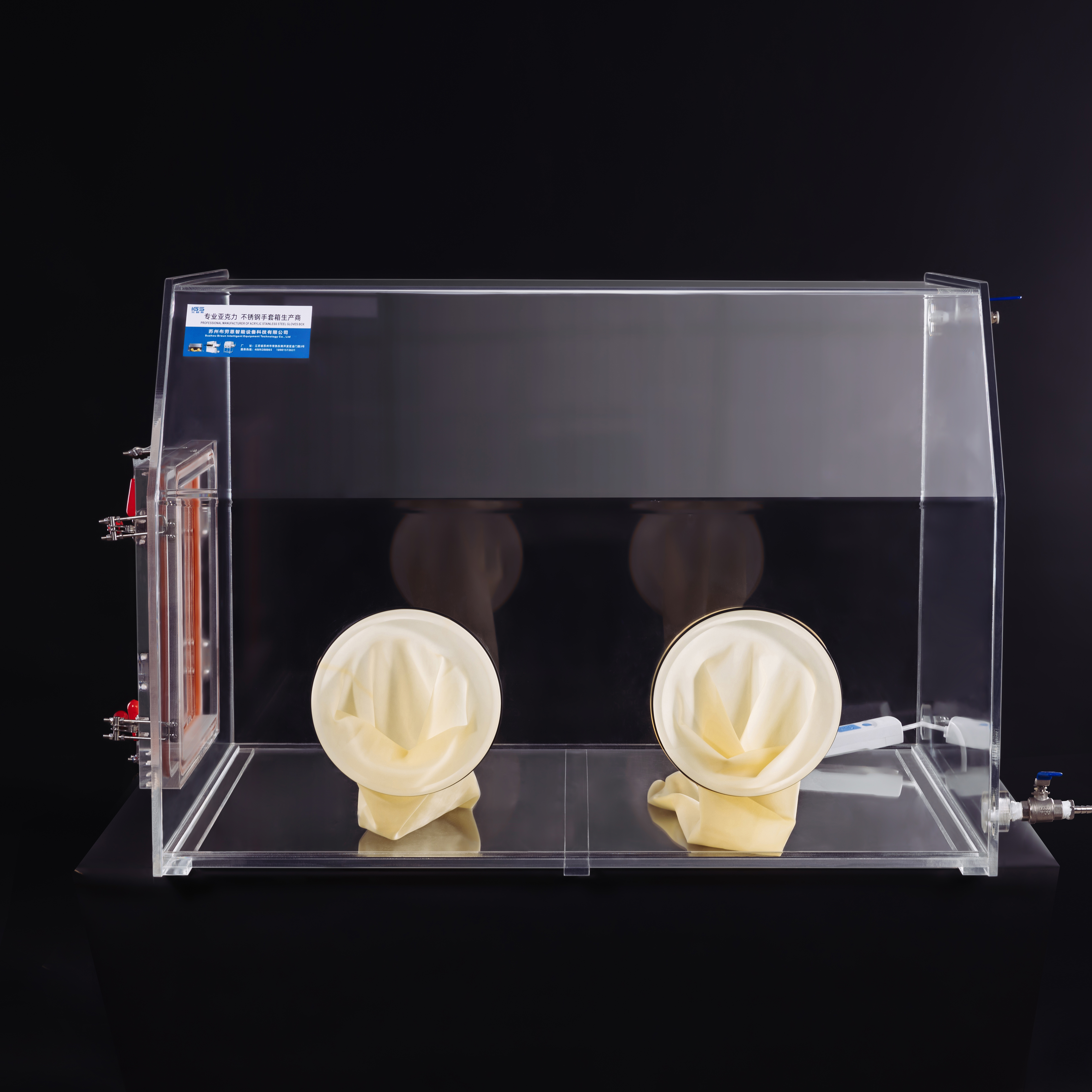

Glovebox chemistry is a cutting-edge technology that allows for the handling of air- and moisture-sensitive compounds in a completely controlled environment. The main functions of a glovebox include the provision of an inert atmosphere, typically using gases like nitrogen or argon, to prevent unwanted reactions with air or moisture. Technological features of glovebox systems often include automated pressure and gas flow regulation, integrated heating and cooling capabilities, and advanced filtration systems to maintain ultra-pure conditions inside the workspace. These systems are used across various fields including pharmaceuticals, materials science, and organic synthesis, enabling precise and safe handling of delicate compounds. The applications are vast, from the synthesis of new drugs to the manufacturing of electronic components, where even the slightest contamination can compromise the integrity of the product.